TITAN - Stop Motion for Extrusion

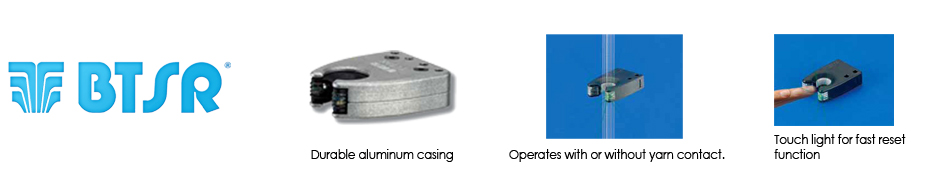

The Titan sensor is comprised of an IS3F sensor with a durable Aluminum compound protective casing. This is to add greater protection with extreme environmental working conditions (such as extrusion) and when using thick, strong yarns (such as tyrecord, carbonium, & glass fibre). The casing protects the sensor, while keeping the open end shape for easy self-threading.

The IS3F series devices, synthesis and result of the continuous BTSR research activities, are electronic sensors specifically designed to detect and control, thanks to a sophisticated patented control technique (bi-dimensional analysis with optical lens/ceramic), the image variation of a running yarn put under control, indicating with absolute certainty the relevant running or stationary condition of the yarn itself.

The "Image Variation" patented technique allows monitoring the running/stop condition of the yarn, through the profile analysis and detection of its image variation within a wide reading area. The bi-dimensional image variation technique makes the IS3F.. device free from environmental conditions such as: machine vibrations, dust/dirtiness accumulation, water/oil contamination (IP67 certification), thus guaranteeing the correct device operation even in the most critical applications.

Thanks to patented control technologies and to the use of last generation materials, the BTSR sensors (IS3 Image Smart Scanning Sensors) represent an exclusive solution on the market, featuring a dual mode operation: with or without yarn contact ('self-cleaning' and 'touch-less'). The IS3F.. devices are fully programmable and easily adaptable to the control of any type of yarn.

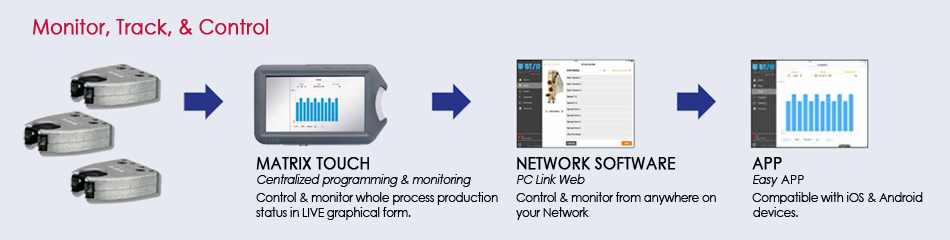

BTSR'S stop motion system offers multiple levels of visibility & control:

Automated Stops & Alerts - BTSR's automated alert system makes the operator immediately aware of any problems & helps the operator quickly identify where the stop is located.

24/7 Operator Management - BTSR let's you manage your employees when your not there. You can effectively monitor & track detailed performance data for every operator shift, & day.

LIVE Production Status - Know your exact production, waste, & efficiencies 24/7. You can immediately react rather than waiting until the next day for production calculations. View from anywhere on your network or smart phone.

Additional Info & Videos