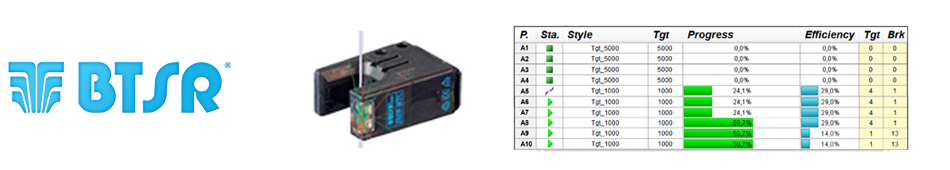

MTC - Target Metering

MTC represents an advanced and innovative production control system specifically developed forto the DRUM function, which determines the cylinder development, i.e. the amount of yarn that will be wound on the cone during every stroke, it will be possible to program the number of meters required for each spool (TARGET) in accurate and reliable way and to automatically stop the position as soon as the previously programmed TARGET value is reached. A dedicated function (COUNT) enables the real time display of wound meters. It obtains an exact meter count of the yarn collected on the individual cones in yarn preparation textile processes (winding, doubling machine,...).

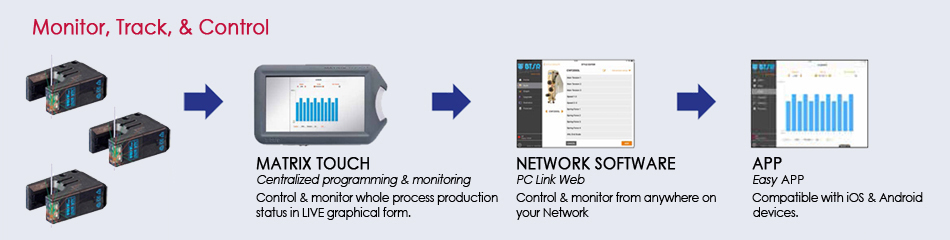

The MSC devices are fully programmable and easily adaptable to the control of any type of yarn. The MTC system provides complete visibility over multiple aspects of the yarn process. From a single source, you are able to automate multiple levels of your yarn process. The MTC system offers multiple levels of visibility & control:

1. METERING- Yarn can be run to precise length with our target metering capabilities. On a 10,000 meter run, it is accurate to within 3 meters. It can calculate production/waste in length.

Yarn Consumption Status - It shows the amount of yarn consumption in Meters/Yards per package & total for every position, machine, & plant.

2. STOP MOTION / PRODUCTION TRACKING - As with all our sensors, the TMS provides LIVE production tracking which can connect to our Network software, giving you automation at multiple levels. This cloud based system monitors & tracks all yarn stops, breaks, & doffs for showing production/waste in real time. It can also connect to any PC or smartphone to give you instant visibility of your production from anywhere in the world.

Automated Stops & Alerts - BTSR's automated alert system makes the operator immediately aware of any problems & helps the operator quickly identify where the stop is located.

24/7 Operator Management - BTSR lets you manage your employees when you're not there. You can effectively monitor & track detailed performance data for every operator shift, & day.

LIVE Production Status - Know your exact production, waste, & efficiencies 24/7. You can immediately react rather than waiting until the next day for production calculations. View from anywhere on your network or smart phone.

Additional Info & Videos